BLOG

Optimising Wine Production: Air Compressor Applications in Wineries

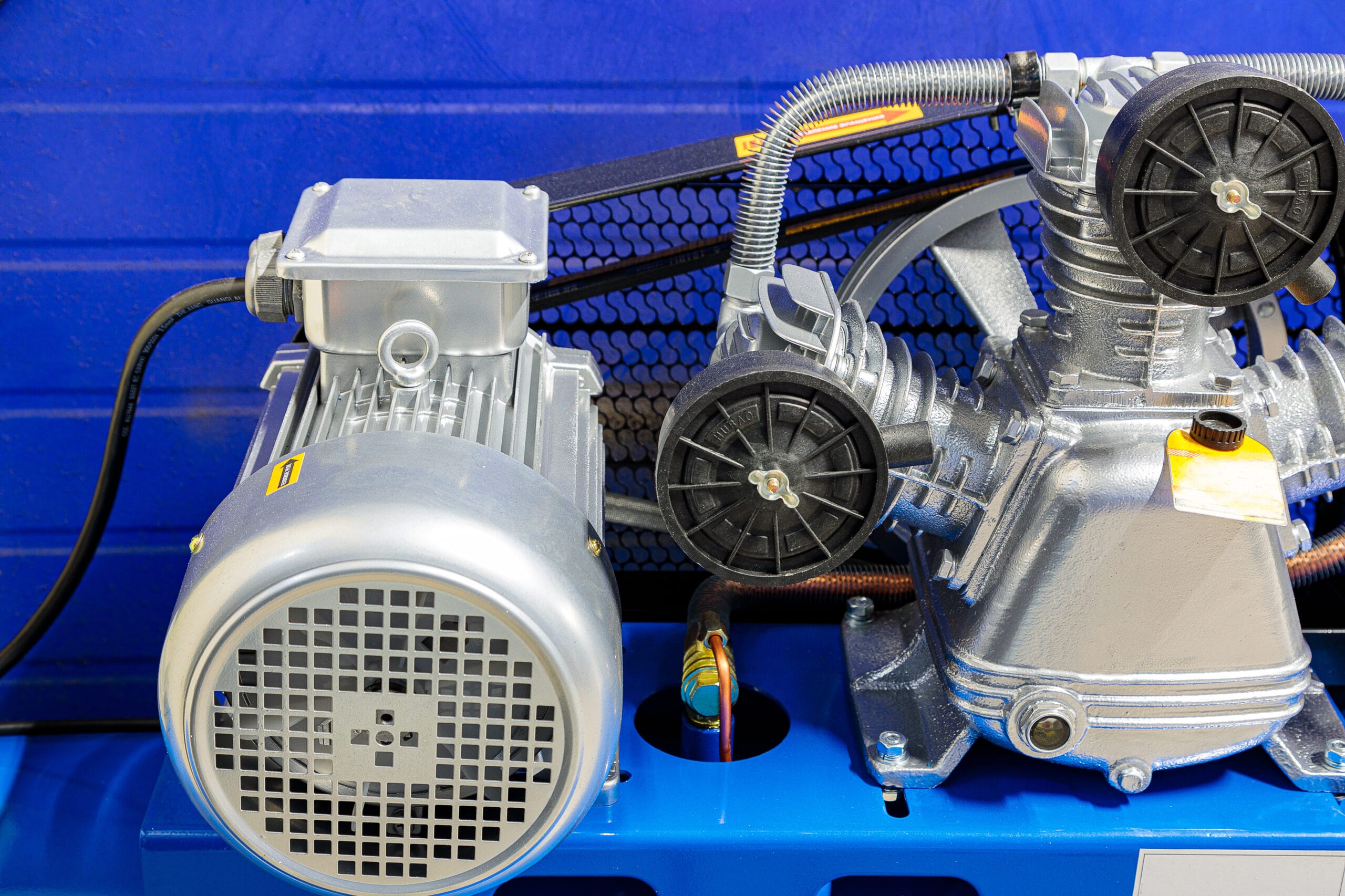

Air Compressor applications in wineries play a crucial role in various stages of the winemaking process. They are used for cleaning and sanitising equipment, which ensures the highest standards of hygiene.

In the bottling stage, air compressors provide the necessary power for efficient and precise filling. Additionally, they power pneumatic tools used throughout the winery. During the winemaking process, air compressors assist in pressing grapes, aerating wine, and controlling temperature.

These functions are vital for maintaining the quality and consistency of the wine. The efficiency and reliability of air compressors are key to upholding the high standards expected in wine production.

By contributing to the cleanliness and overall quality of the process, air compressors play a significant role in producing exceptional wines.

The Role of Air Compressors in Modern Winemaking

Winemaking has undergone significant changes over the centuries, evolving from a traditional craft to a sophisticated, technology-driven process. Modern technology, including the integration of air compressor efficiency in winemaking, has played a pivotal role in this transformation, enhancing both efficiency and quality in various stages of winemaking.

Historical Context:

Traditionally, winemaking was a labour-intensive process involving manual methods for tasks such as crushing grapes and pressing juice. Techniques varied across regions, often relying on rudimentary tools and the experience of vintners passed down through generations. These methods, while effective, were time-consuming and less consistent in quality.

Modern Advancements:

The introduction of modern technology has revolutionised winemaking. Automated machinery, precise control systems, and advanced equipment have replaced many manual processes. Among these technological advancements, air compressors have become indispensable.

Key Transformations with Air Compressors:

- Grape Pressing:

- Traditional: Manual pressing using wooden or stone presses requires significant physical effort and time.

- Modern: Air compressors power bladder presses, which use pressurised air to gently but efficiently extract juice from grapes. This method ensures maximum yield with minimal damage to the grapes, preserving the quality of the juice.

- Grape Crushing:

- Traditional: Grapes were often crushed by foot, a method that, while romanticised, lacked consistency and hygiene.

- Modern: Air compressors facilitate the use of automated bladder presses, which crush grapes uniformly and hygienically, improving the consistency and quality of the must.

- Temperature Control:

- Traditional: Controlling fermentation temperatures relied on ambient conditions and rudimentary cooling methods.

- Modern: Air compressors are integral to advanced heating and cooling systems, maintaining precise temperatures during fermentation. This control prevents unwanted temperature fluctuations that can spoil the wine, ensuring a consistent and high-quality product.

- Aeration:

- Traditional: Limited to natural aeration, which was less controllable.

- Modern: Compressed air is used to introduce oxygen in controlled amounts during aeration, enhancing the wine’s flavour and texture before bottling.

- Bottling:

- Traditional: Manual bottling was slow and prone to contamination.

- Modern: Automated bottling lines, powered by compressed air, efficiently transfer wine from tanks to bottles. This method is faster, more hygienic, and ensures a clean and uncontaminated product.

- Labelling:

- Traditional: Labels were applied by hand, leading to inconsistencies.

- Modern: Compressed air systems in labelling machines ensure labels are applied uniformly and neatly, enhancing the professional appearance of the product.

- Sparging:

- Traditional: Sparging methods were rudimentary, often resulting in residual oxygen that could spoil the wine.

- Modern: Compressed air is used to introduce nitrogen bubbles in sparging, effectively removing residual oxygen and improving the wine’s stability and taste.

Key Applications of Air Compressors in Wineries

Air compressors play vital roles in wineries, facilitating equipment cleaning, ensuring a sterile environment for production, and providing pressure for efficient bottling.

They aid in grape pressing to extract juice without contamination and in aerating wine for flavour enhancement. These applications boost efficiency, maintain hygiene standards, and elevate wine quality.

Winery air compressor systems are essential components in the seamless operation of these processes.

Why is compressed air necessary in the winemaking process?

Compressed air is crucial in the wine production process, significantly contributing to energy consumption, especially during grape production. Numerous machines involved in winemaking rely on compressed air to operate efficiently, ensuring a clean process and a high-quality final product.

Why do wineries require air compressors?

Wineries require air compressors for grape processing, crucial in winemaking equipment efficiency. Compressors should be in ventilated, shaded spots, away from direct sunlight and heat sources like outlets or refrigeration units.

Bottling: Ensuring Precision and Speed

In the bottling process, air pressure regulation is crucial for maintaining consistent pressure, ensuring precise filling, and speeding up production.

They provide the necessary pressure to fill bottles accurately, preventing overflows or underfills. This consistency ensures that each bottle contains the correct amount of wine, maintaining product quality.

Additionally, air compressors help automate the bottling line, increasing production speed and efficiency.

By streamlining this process, wineries can meet higher production demands while maintaining the high standards expected in winemaking.

Air compressors play a vital role in bottling by:

- Maintaining Pressure: They ensure consistent air pressure, crucial for smooth wine transfer without turbulence or air bubbles, preserving quality.

- Filling Precision: Compressor-controlled pressure enables accurate filling levels, preventing over or underfilling, and ensuring precise wine amounts in each bottle.

- Boosting Efficiency: Powering pneumatic systems like capping and labelling machines, and compressors accelerate production, increasing bottling facility output.

Labelling: Enhancing Accuracy and Consistency

Air compressors play a vital role in the labelling process by ensuring labels are applied accurately and consistently on every bottle. They power pneumatic systems that control the precise placement and adhesion of labels.

This automation ensures that each label is applied uniformly, reducing errors and misalignments. By maintaining consistent pressure, air compressors help achieve a professional and polished appearance for each bottle, enhancing the overall presentation of the wine and maintaining brand integrity.

The role of air compressors in the labelling process:

- Powering Machinery: Air compressors provide the necessary power to the machines that apply labels to wine bottles.

- Ensuring Precision: They help ensure that each label is affixed cleanly and consistently, reducing errors like misalignment or wrinkles.

- Increasing Efficiency: Automation powered by air compressors speeds up the labelling process, making production more efficient.

- Maintaining Steady Airflow: They maintain a consistent airflow, essential for a streamlined and professional labelling process.

- Supporting Brand Recognition: A precise and efficient labelling process helps create a uniform look for each bottle, aiding in brand recognition.

- Conveying Important Information: Proper labelling provides consumers with key details about the wine, including its age, origins, and grape variety.

Packaging: Streamlining Operations

Air compressors streamline packaging, ensuring product integrity by powering secure sealing, preventing leaks, and preserving wine quality. They create vacuum packs, extending shelf life. This automation enhances efficiency, and reduces manual labour, ensuring high-quality products.

Air compressors play a crucial role in the packaging process by providing a reliable source of compressed air that powers various packaging machinery.

Here’s how they aid in different stages of packaging:

- Air compressors operate pneumatic sealing machines to ensure wine bottles are tightly sealed, preventing leaks and preserving product quality.

- In vacuum packaging, air compressors remove air from the packaging to extend the shelf life of wines by reducing oxygen exposure.

- Air compressors power the pneumatic systems in filling and capping machines, ensuring precise filling and secure sealing of wine bottles.

- Compressed air is used in labelling machines to apply labels accurately on wine bottles, maintaining a professional and consistent appearance.

- Air compressors power pneumatic palletising systems, efficiently stacking and arranging packaged wine bottles onto pallets for transport.

Maintaining Controlled Atmospheres

Maintaining controlled atmospheres is crucial for wine storage and ageing, as it helps preserve wine quality and flavour. Air compressors are essential in this process, providing the necessary pressure to regulate and control environmental conditions such as temperature, humidity, and oxygen levels.

By ensuring a stable and controlled atmosphere, air compressors prevent oxidation and spoilage, allowing wines to age gracefully and develop their full potential. This precise control is vital for maintaining the integrity and quality of the wine throughout the storage and ageing process.

For both short-term and long-term wine storage, follow these straightforward guidelines:

- Store wine in a location where temperatures do not exceed 20°C (68°F).

- Avoid the kitchen or laundry room due to temperature and humidity changes from cooking and washing.

- Keep wine away from direct sunlight, ideally in a dark place.

- Avoid storing wine near strong-smelling foods and household products to prevent contamination through the cork.

- Minimise vibrations by storing wine in low-traffic areas and ensuring bottles are well-packed during shipping.

Benefits of Using Air Compressors in Wineries

Using air compressors in wineries offers numerous advantages that improve overall operations and product quality.

Firstly, air compressors enhance efficiency by powering essential tasks like cleaning, bottling, and labelling, reducing manual labour, and increasing productivity.

Secondly, they contribute to cost savings by automating processes and reducing the need for manual interventions, leading to lower operating costs. Additionally, air compressors ensure consistent quality by maintaining precise pressure and control during various winemaking stages, resulting in superior wines.

Lastly, their reliability minimises downtime, ensuring continuous production and consistent output, ultimately benefiting the winery's bottom line.

Choosing the Right Air Compressor for Your Winery

When choosing the right air compressor for your winery, consider several key factors to ensure it meets your specific needs effectively.

First: Assess the size of your operation and the air demand of each application to determine the appropriate compressor size and capacity.

Secondly: Consider the power source and energy efficiency of the compressor, opting for models that match your winery's power supply and offer energy-saving features to minimise operating costs.

Additionally, prioritise reliability and durability, selecting compressors from reputable brands known for their quality and longevity.

Lastly: Evaluate the maintenance requirements and availability of service and support to ensure smooth and uninterrupted operation.

Maintenance and Safety of Air Compressors in Wineries

Regular maintenance and strict safety adherence are crucial for air compressors in wineries. Consistent cleaning, lubrication, and inspection prevent failures and costly repairs.

Following manufacturer guidelines and implementing safety protocols, including operator training and pressure relief valve installation, is essential.

Prioritising maintenance and safety maximises compressor efficiency, reliability, and safety, safeguarding against accidents and breakdowns.

Preventive maintenance for industrial air compressor systems offers numerous advantages and value:

- Avoiding Operational Downtime

- Cost-Efficiently Evading Emergency Repairs

- Decreasing Energy Expenditure

- Extending Air Compressor Lifespan and Efficiency

Case Studies: Successful Implementation of Air Compressors in Wineries

Air compressor applications in wineries are found in various operations such as pneumatic harvesting machines, pneumatic presses, and bottling lines. They contribute to improved efficiency, cost savings, and enhanced product quality by providing consistent pressure for pneumatic tools used in maintenance tasks and facilitating the smooth operation of pneumatic actuators in valve controls.

Two standout examples of wineries effectively utilising air compressors are Brown Brothers in Victoria's King Valley region and Wirra Wirra Vineyards in McLaren Vale, South Australia.

Brown Brothers integrated air compressors into their production lines to boost efficiency and maintain product quality. By utilising compressors for bottling and packaging operations, they minimised downtime and ensured consistent pressure for tasks like labelling and sealing bottles. This resulted in streamlined processes, improved productivity, and the ability to meet growing demands while upholding product standards.

Similarly, Wirra Wirra Vineyards adopted air compressors to power pneumatic tools and machinery in their vineyard and cellar operations. This move enhanced the efficiency of tasks such as pruning, bottling, and corking, leading to increased productivity and reduced manual labour. The precise control provided by the compressors also ensured optimal conditions for critical processes like bottling, contributing to consistent product quality.

Future Trends in Air Compressor Technology for Winemaking

Future trends in winemaking air compressor technology promise to transform production processes, with opportunities for enhanced efficiency and quality.

Emerging trends include energy-efficient compressors, using variable speed drives, and improved designs to cut energy usage and costs.

Automation and connectivity advancements allow smarter systems, adjusting performance in real time for optimal efficiency. Innovations in materials and construction aim for durable, reliable systems that endure harsh winery conditions.

The Dominant Technological Shifts Reshaping the Wine Sector

- Precision Viticulture: Utilising satellite data, drones, and sensors to enhance vineyard management for improved grape quality and sustainable practices.

- Machine Learning and Artificial Intelligence: Predicting grape ripeness, optimal harvest times, and disease outbreaks while providing personalised wine recommendations based on sensory analysis.

- Biotechnology and Genomics: Revolutionising grape breeding for resistance to pests, diseases, and environmental stressors, leading to sustainable vineyard management and reduced pesticide use.

- Digital Marketing and E-commerce: Leveraging social media, email campaigns, and e-commerce platforms for brand building, consumer engagement, and convenient wine purchasing experiences.

- Augmented Reality (AR) and Virtual Reality (VR): Enhancing consumer engagement with interactive wine labels and immersive virtual wine tours, offering insights into the origin, tasting notes, and food pairings.

- Smart Packaging and IoT: Transforming wine storage and enjoyment with temperature-sensitive labels, NFC-enabled tags for provenance, and IoT devices for optimal serving conditions.

- Blockchain Technology: Providing enhanced traceability and authenticity throughout the wine supply chain, ensuring secure, tamper-proof records from vineyard to glass.

Maximising Efficiency and Quality in Winemaking

Air compressor applications in wineries are indispensable for enhancing efficiency and maintaining quality throughout the winemaking process. From pneumatic presses to bottling lines, air compressors power essential machinery, streamlining operations and reducing manual labour.

By ensuring consistent pressure levels and precise control, these systems contribute to the uniformity and excellence of wine production. Wineries should prioritise the integration of air compressors to minimise downtime, increase productivity, and uphold the integrity of their wines.

Embracing this technology underscores a commitment to innovation and elevates the standard of winemaking, ultimately enhancing the reputation and profitability of vineyards.