BLOG

Maximise ROI: How Efficient Air Compressors Reduce Mining Costs

In South Australia’s resource-driven economy, choosing the right compressor can make a significant impact on both performance and profitability.

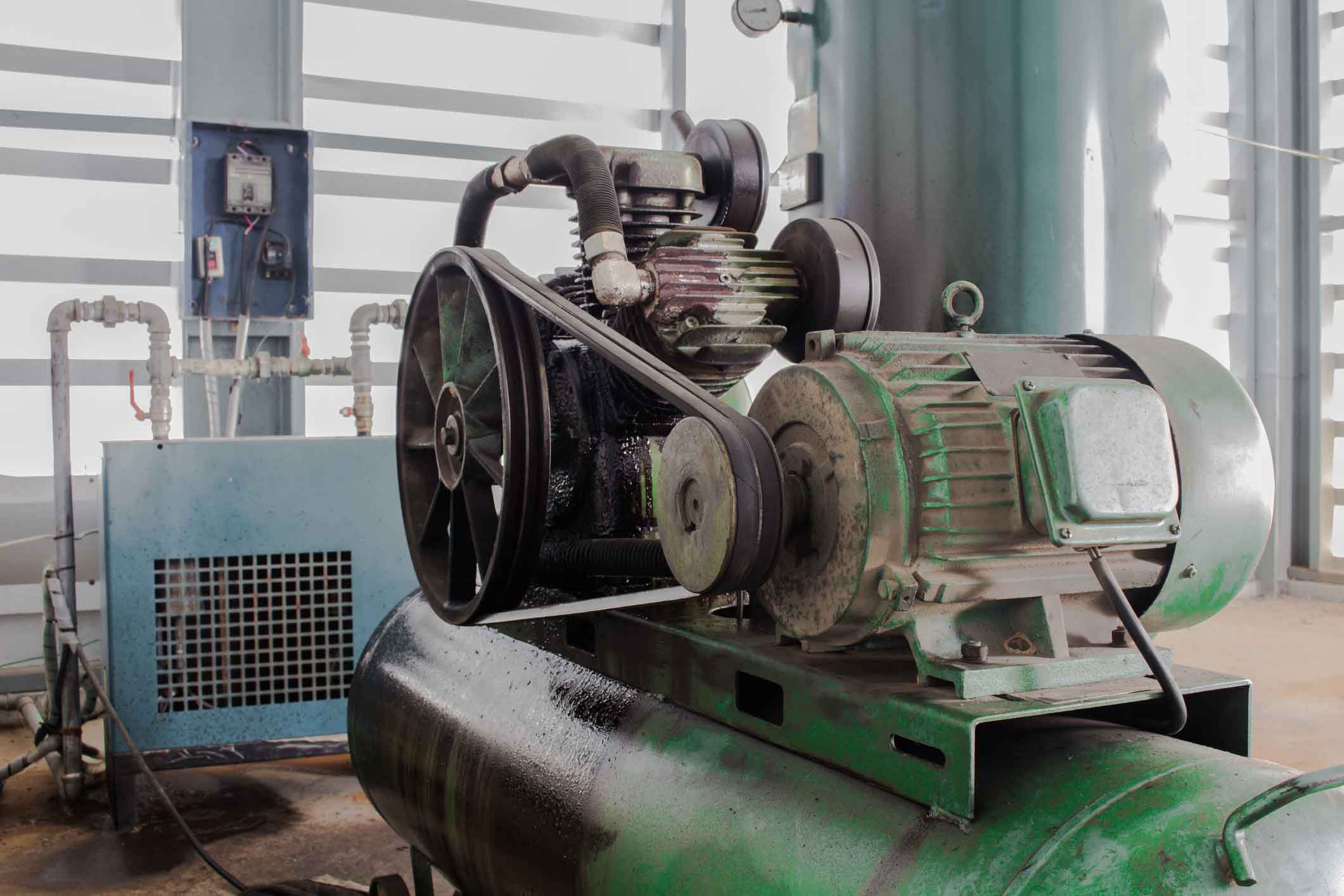

Air compression is essential to mining operations, powering everything from drilling equipment to ventilation systems. However, inefficient compressors can lead to high energy costs, frequent breakdowns, and costly downtime, eating into profits. Upgrading to efficient air compressors for mining can significantly reduce operating expenses, improve reliability, and maximise return on investment (ROI). This article explores how advanced air compression technology helps mining companies cut costs, boost productivity, and extend equipment lifespan, making operations more efficient and profitable.

Understanding the True Cost of Air Compression in Mining

Air compression is a critical component of mining operations, powering equipment such as drills, conveyors, and ventilation systems. However, inefficient air compression systems can significantly impact a mining company's bottom line. The true cost of air compression goes beyond the initial equipment purchase, encompassing three major expense areas:

- Energy Consumption: Compressed air accounts for a substantial portion of a mine’s total energy use, often exceeding 30% of electricity consumption. Inefficient systems lead to excessive power usage, increasing operational costs.

- Maintenance Expenses: Older or poorly maintained compressors require frequent servicing, leading to higher maintenance expenses. Leaks, pressure drops, and mechanical failures further exacerbate costs.

- Downtime Costs: Unplanned compressor failures can halt production, leading to significant revenue loss. In mining, where time is money, ensuring continuous operation is crucial to profitability.

Inefficient air compressors lead to wasted energy, excessive maintenance requirements, and costly downtime, ultimately draining profits from mining operations. Upgrading to efficient air compression technology can mitigate these risks while improving overall operational performance.

How Efficient Mining Air Compressor Maximise Cost Savings

Frequent breakdowns and maintenance disruptions can be costly and time-consuming. Inefficient air compressors suffer from excessive wear and tear, leading to more frequent repairs and premature equipment failure.

- Advanced Filtration and Lubrication Systems – Modern compressors are designed with high-efficiency filters and superior lubrication mechanisms that reduce internal friction and prevent contaminants from damaging components. This minimizes wear and extends service life.

- Fewer Mechanical Failures – Improved design and high-quality materials mean fewer moving parts and less risk of critical component failure, reducing repair costs and unplanned downtime.

- Predictive Maintenance Features – Many modern air compressors come equipped with smart monitoring systems that track performance metrics and alert operators before a potential issue arises. This allows for proactive maintenance, preventing costly breakdowns.

- Longer Service Intervals – More efficient cooling and filtration systems reduce the need for frequent servicing, extending the time between maintenance checks and reducing labour costs.

By reducing maintenance needs, mining operations save thousands of dollars annually while improving operational reliability and extending equipment lifespan.

Calculating ROI: Key Metrics for Mining Operations

Air compressor ROI calculation is key to understanding its long-term cost savings, energy efficiency, and impact on mining operations. To determine the financial impact of upgrading to efficient air compressors for mining, companies should evaluate the following ROI metrics of air compressors in mining:

- Energy Cost Savings Over Time: By comparing electricity consumption before and after implementing an energy-efficient model, mines can calculate annual industrial air compressor savings. With energy-efficient compressors reducing consumption by up to 50%, the savings can be substantial.

- Lower Maintenance and Repair Expenses: Tracking maintenance costs helps determine how much is spent on servicing inefficient compressors. Mines that upgrade to modern systems often experience a 40–60% reduction in maintenance costs over time.

- Productivity Gains and Faster Project Completion: A reliable air compressor improves workflow efficiency, leading to faster project turnaround. Mines should measure the increase in uptime and production output to determine the financial benefits of reducing downtime and improving operational consistency.

- Total Cost of Ownership (TCO) Comparison: While high-efficiency air compressors may have a higher upfront investment, their lower operating costs, reduced maintenance, and improved lifespan contribute to greater long-term savings compared to traditional models.

Why Titan Air Compressors Deliver Maximum ROI

Mining operations demand high-performance equipment that can operate efficiently under extreme conditions while keeping costs under control. Titan Air Compressors are engineered for high-performance across demanding industries like mining, manufacturing, and food production—making them ideal for South Australia’s toughest environments.

Combining cutting-edge technology with robust durability to ensure maximum return on investment (ROI). Here’s why Titan compressors stand out as the superior choice for mining operations:

- Variable Speed Drive (VSD) Technology – Traditional air compressors often run at full capacity regardless of demand, leading to unnecessary energy waste. Titan’s VSD technology adjusts motor speed dynamically based on actual air demand, significantly reducing power consumption by up to 50% compared to fixed-speed models.

- Smart Control Systems – Advanced monitoring and automation systems continuously track energy consumption, detect inefficiencies, and prevent overuse. These systems help operators fine-tune performance, ensuring that the compressor only consumes as much power as necessary.

- Heat Recovery Systems – A major portion of the energy used in air compression is converted into heat. Instead of letting this energy go to waste, Titan compressors are equipped with heat recovery options that allow excess heat to be repurposed for applications such as heating water or pre-warming air for other mining processes. This feature further reduces the mine’s overall energy expenditure.

By implementing Titan Air Compressors mining solutions, operations can drastically cut their electricity bills, improving cost efficiency without compromising air supply reliability.

Maximising Mining Productivity with Efficient Air Compressors from Titan Air Compressors

Choosing an efficient air compressor for mining can make a significant difference when it comes to operations. With mining equipment energy efficiency, reduced maintenance costs, and improved productivity, upgrading to an efficient compressor is one of the smartest investments a mining company can make.

Ready to optimise your mining operations?

Contact Titan Air Compressors today and discover how our industry-leading technology can help you cut costs and maximise profitability.

Visit https://titanaircompressors.au/ or call 0451 499 733.