BLOG

Choosing the Right Size Air Compressor for Bottling Lines

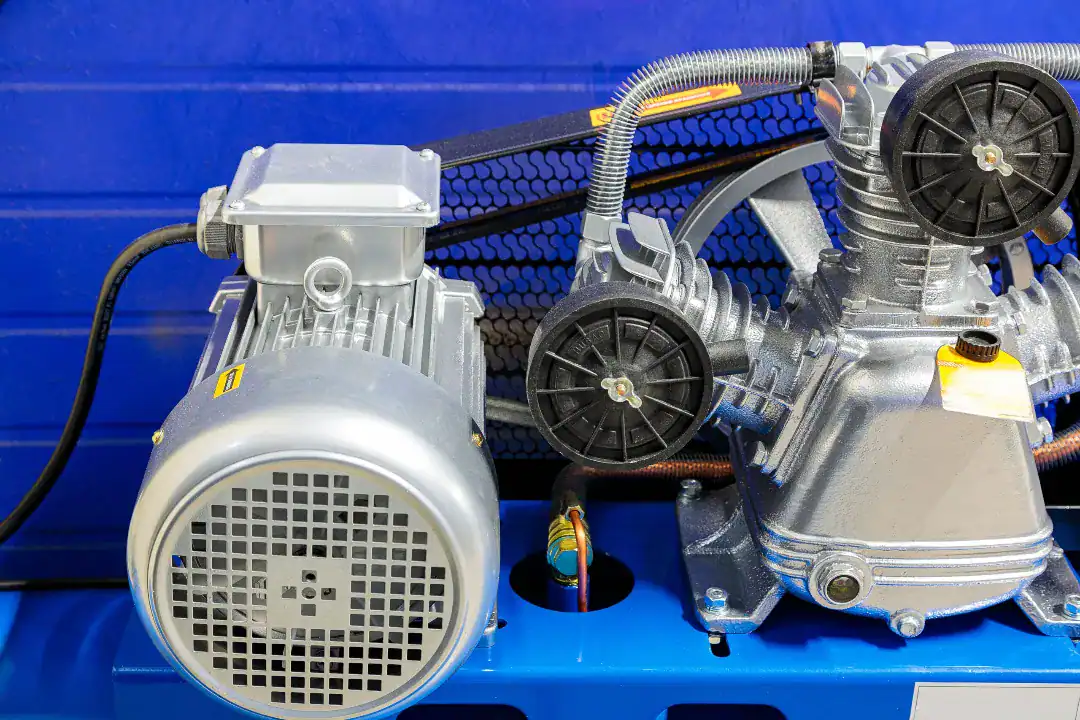

Choosing the right size air compressor for bottling lines is one of the most important decisions a production manager can make. Whether you run a small operation or a multi-stage bottling plant, the performance of your compressor directly affects your efficiency, maintenance needs and output quality.

The best air compressor for bottling is one that meets the airflow, pressure and duty demands of your equipment without overworking or wasting energy. An undersized unit leads to delays and wear. An oversized one increases costs and strain.

Understanding Your Bottling Line's Airflow and Pressure Needs

Compressed air powers almost every key function in a bottling line. From filling machines to capping units and labelling stations, your equipment depends on consistent airflow and pressure. The two most important numbers to consider are CFM (cubic feet per minute) and PSI (pounds per square inch).

- CFM tells you how much air is being delivered. If your compressor does not keep up with demand, your machines will slow down or stall.

- PSI refers to the force of the air. If pressure drops below your system’s requirements, output will suffer and products may be rejected.

Getting these values right is not about guesswork. It requires understanding the total air usage of your line at full capacity. At Titan Air Compressors, we work with clients across Adelaide and South Australia to evaluate demand across every station. This helps prevent costly miscalculations that affect your bottom line.

Need help calculating your bottling line’s CFM and PSI requirements? Contact our Adelaide team for expert advice and product recommendations.

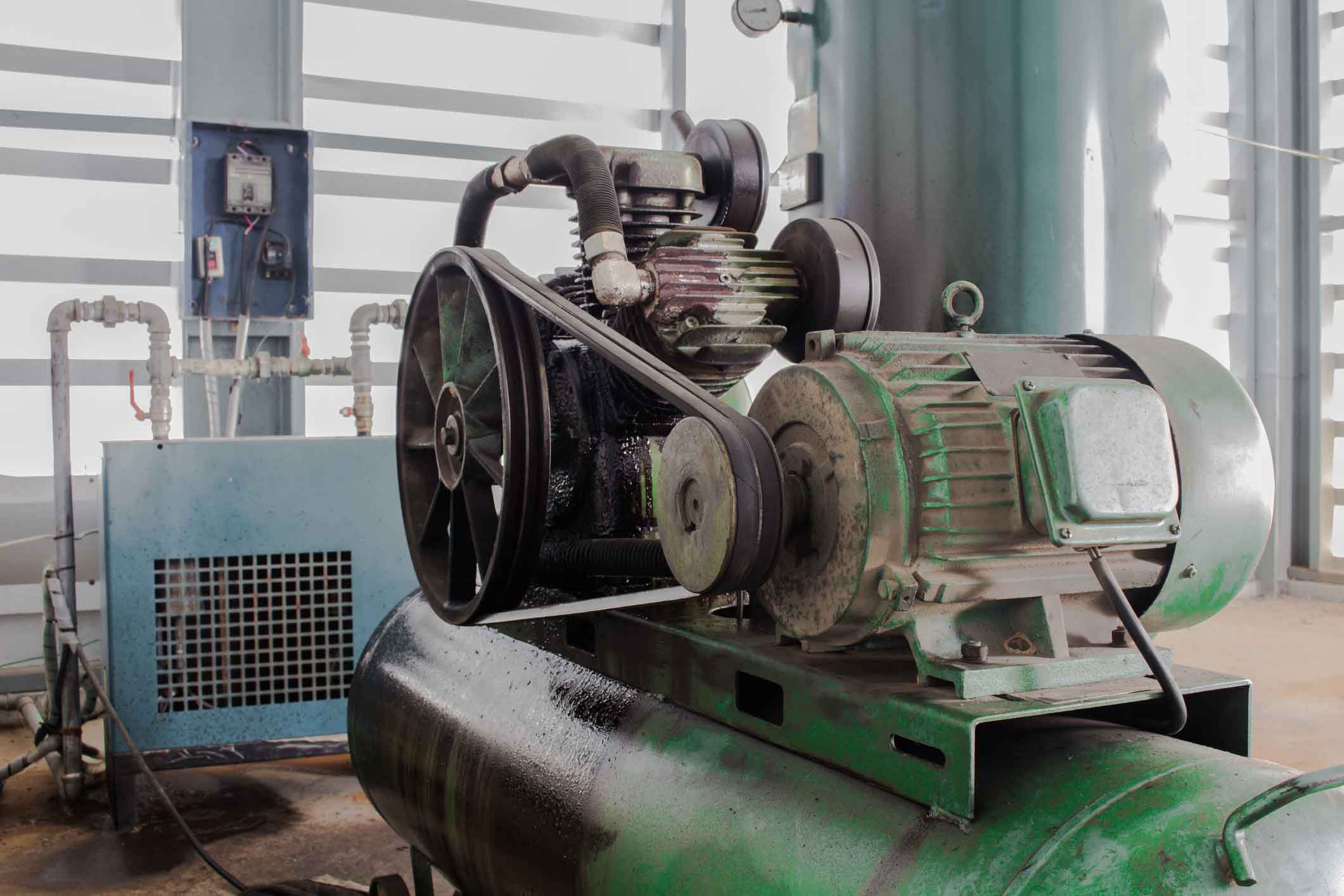

Why Duty Cycle Matters for Bottling Applications

The duty cycle of your compressor tells you how long it can operate continuously without needing a break. In bottling facilities, where machines often run through entire shifts, this becomes a key factor in system reliability.

For example, a compressor with a 50 percent duty cycle can only operate for half of any ten-minute window. If your production needs more sustained power, this leads to shutdowns, slowdowns and higher maintenance costs. On the other hand, a compressor with a 100 percent duty cycle is designed for nonstop use during heavy production hours.

Bottling operations usually benefit from continuous-duty compressors. These are built for demanding applications where compressed air is needed steadily across multiple machines. They also reduce the risk of overheating and wear over time.

At Titan Air Compressors, we supply high-performance continuous-duty units that are trusted by manufacturers across South Australia. We can help you match your compressor’s duty cycle with the operating rhythm of your line so that output never slows down due to a tired machine.

Looking for a compressor that can keep pace with your busiest production days? Our team will guide you to the most dependable options.

The Risks of Undersizing or Oversizing Your Compressor

Getting the size wrong can cost you more than just efficiency. A compressor that is too small or too large for your line can create issues that ripple across your entire operation.

An undersized compressor will struggle to meet demand. This causes pressure drops, inconsistent operation and frequent stops. It can also lead to accelerated wear on the unit itself, increasing maintenance costs and reducing lifespan. Worse still, product quality may suffer if air-driven machines fail to operate smoothly or consistently.

An oversized compressor presents a different challenge. It may seem like a safer option, but using a machine that delivers more power than you need can drive up your energy bills. These systems often short cycle, turning on and off too frequently. This increases strain on components and leads to unnecessary wear over time.

At Titan Air Compressors, we help you avoid both extremes. Our team takes into account your equipment specs, daily operating hours and growth plans. This ensures the compressor you choose is tailored to your real-world conditions, not just a rough estimate.

Unsure if your current compressor is too much or not enough? Reach out for a pressure and flow assessment tailored to your bottling setup.

Making a Smart Investment with Expert Support

Choosing the right air compressor size is about more than ticking off technical specs. It is about investing in reliability, productivity and cost control over the long term. The right system will support your bottling line day in and day out, without wasting energy or slowing you down.

Partnering with a local expert can make all the difference. At Titan Air Compressors, we work directly with South Australian bottling facilities to recommend systems that fit the job perfectly. We provide:

- Honest assessments based on real production demands

- Guidance on matching CFM, PSI and duty cycle to your needs

- Access to reliable industrial compressors built for performance

- Ongoing support from our Adelaide-based team

If you are scaling up, switching equipment or simply want peace of mind, we can help you avoid the hidden costs of a poor match.

Explore our full range of industrial air compressors or speak to a technician today. The right fit is closer than you think.