BLOG

What to Look for in an Air Compressor for Mining and Drilling Projects

Selecting the right air compressor for drilling and blasting is crucial for ensuring safety, efficiency, and cost-effectiveness in demanding environments such as quarries and mine sites. Whether you're breaking through tough rock formations or powering heavy-duty tools, having a reliable air compressor for mining operations can significantly enhance performance and productivity. With various compressor types, capacities, and features available, selecting the best fit requires a clear understanding of your project needs and site conditions. In this guide, we’ll walk you through the key factors to consider when choosing an air compressor tailored specifically for drilling and blasting applications.

Understanding Air Compressor Size and Capacity for Drilling and Blasting

Choosing the right air compressor for drilling and blasting starts with understanding the specific demands of your project. Different rock types, hole depths, and drilling methods all affect how much air volume and pressure you’ll need on site. If your compressor can’t keep up, you risk reduced efficiency, longer drilling times, and inconsistent blasting results. That’s why airflow (CFM) and pressure (PSI) ratings should match the tools and processes you’re using—getting this right is key to a safe and productive operation.

For mining operations, especially in remote or high-demand environments, it’s worth investing in the best air compressor for mining. These compressors are built to deliver consistent performance over long shifts and tough terrain. Oversized units may waste fuel and inflate costs, while undersized systems can stall productivity. The goal is to strike a balance—enough power to meet your drilling and blasting requirements, without unnecessary overcapacity. Taking the time to size your compressor correctly pays off in both performance and long-term savings.

Pressure Requirements for Efficient Drilling and Blasting Operations

Pressure is just as important as airflow when selecting the right air compressor for drilling and blasting. Different drilling and blasting applications require varying pressure levels, depending on factors such as rock hardness, borehole size, and drilling depth. For example, shallow holes in softer rock may only need moderate pressure, while deep boreholes or hard rock formations demand significantly higher PSI to break through efficiently. Using a compressor that can’t meet these demands can lead to sluggish drilling, incomplete breakage, and higher fuel consumption.

Understanding air compressor pressure requirements is essential for aligning your equipment with the job at hand. A mismatch between your compressor’s output and your actual pressure needs can reduce productivity and even damage tools over time. The key is to select a compressor that provides steady, reliable pressure across your entire operation, especially if multiple drills or tools are running at once. By choosing a compressor that matches both pressure and flow requirements, you set your team up for smoother, faster, and more cost-effective drilling and blasting outcomes.

Durability and Reliability: Key Factors for Harsh Environments

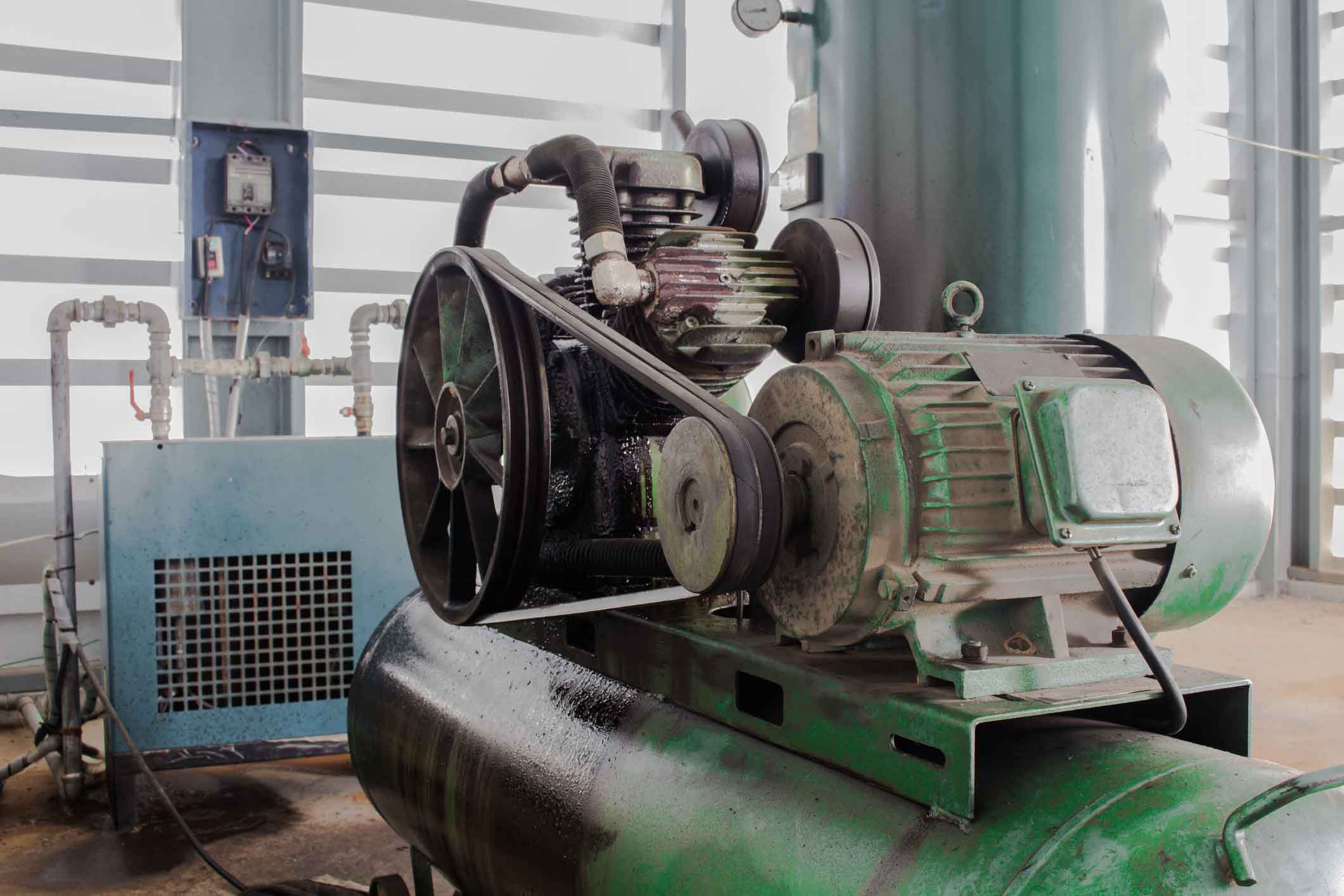

When working in tough conditions, like the high heat of mining sites, the constant dust at quarries, or the fast pace of large construction projects, equipment failure can cause more than just inconvenience. It can stop all operations. That’s why the durability of air compressors plays a critical role in selecting the right machine for the job. An air compressor used for drilling and blasting needs to be built to handle repeated impacts, fluctuating weather, high vibration levels, and long hours of continuous operation without faltering. It's not just about rugged construction; it’s about consistent, dependable performance under pressure.

For professionals who rely on their tools day in and day out, the best air compressor for drilling and blasting is one that requires minimal maintenance while offering maximum uptime. Look for features like heavy-duty filtration systems, corrosion-resistant components, and advanced cooling technologies that prevent overheating and extend the lifespan of your compressor. In air compressors for mining applications, especially, reliability isn’t optional—it’s essential. Operations often run far from service centres, so choosing a compressor that can withstand the harsh realities of remote environments means fewer breakdowns, reduced repair costs, and better safety for your crew. In short, long-lasting durability equals long-term operational success.

Safety Features and Compliance in Air Compressors for Drilling and Blasting

Safety is non-negotiable when it comes to drilling and blasting operations. These high-risk environments demand equipment that not only performs well but also adheres to the highest safety standards. That’s why understanding the safety features in air compressors is critical. From automatic shutdown systems and emergency stop controls to pressure relief valves and advanced cooling mechanisms, these features are designed to protect workers, equipment, and the surrounding environment. Proper ventilation, low-oil level protection, and anti-vibration mounts also help reduce the risk of malfunction and ensure compliance with strict industry regulations.

When it comes to choosing the right air compressor for mining, it’s not just about power and efficiency—it’s about trusting your equipment to perform safely under pressure. Titan Air Compressor stands out in this space by offering high-performance, safety-focused solutions tailored for mining, construction, and other heavy-duty industries. Each unit is engineered with compliance and operator protection in mind, helping you meet both safety standards and operational goals without compromise.

Looking for high-quality industrial air compressors for sale in Adelaide or across South Australia? You've come to the right place. Titan Air Compressor offers a premium range specifically designed to meet the rigorous demands of the mining industry. Our compressors are built with rock-solid reliability, efficiency, and longevity—perfect for everything from manufacturing and construction to any task requiring high-performance compressed air.

We are confident that our exceptional performance will make a significant difference in your operations. Explore our range today and discover the real benefits of partnering with Titan Air Compressor—where safety, strength, and service come standard.